In our understanding the term salvaging means bringing sunken items back to the surface.

Each recovery is unique and requires flexibility in thinking and acting time and time again.

Listed below you can find some exampls of your salvaging work.

In this category we like to give our audience one advice:

"Do not attempt this by yourself!"

Conveyor Belt, 390ft

Salvage of a conveyor belt in Europe's largest gravel works. On Thursday afternoon, Aqua-Nautik received a call for help to salvage a conveyor belt located on the depth grab. In order not to lose any time here, so that the gravel works could run its full production again, the truck was booted and spurred with everything that was needed for a rescue.

The next morning the rescue team from Aqua-Nautik started moving. The first investigation revealed a jumble of conveyor belts on the 100ft deep bottom of the quarry pond. First of all, the conveyor belt on the excavator was secured. In the second step, the floating pontoons and the deformed 260ft long conveyor belt were secured and equipped with buoyancy equipment. After the situation had been inspected, the first 260ft on the ground were lifted and hauled towards the bank. Thanks to the active support of the gravel works staff and the crane company, the entire conveyor belt and its floating pontoons could be lifted ashore within a short period of time.

Even if it is always associated with costs and inconvenience for the production for the operator, it was again an interesting and successful task for the rescue team of Aqua-Nautik.

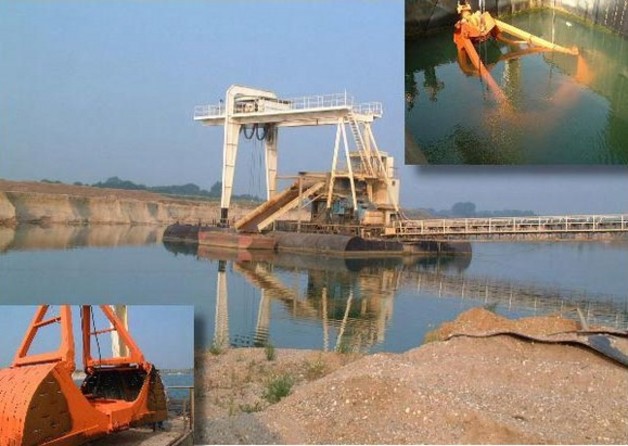

Bucket ladder excavator, 200 ton.

When it went down, the excavator turned by about 135 degrees and was at its deepest point at 45ft. It had a dimension of L x W: 100ft x 20ft. The hardest part was getting the excavator back into the upright position. Through the targeted use of lifting bags and with the help of tractors, it was possible to erect the 200 ton excavator.

After the first section, the lifting bags had to be distributed in such a way that the excavator detaches itself horizontally from the ground in order to be brought ashore. Since there was high water at the time of the rescue, the normal water level was waited on in order to seal, drain and make the excavator buoyant.

The rescue work was carried out in cooperation with Aqua-Nautik GmbH in a subcontractor contract.

Dredging pontoon - salvage of the pontoon

For an unexplained cause, a pontoon with a permanently installed dredger and two push boats sank that were supposed to be salvaged. The pontoon was moored alongside the sheet pile wall with two push boats.

First the two outer push boats were rescued with the help of lifting bags, which together weighed approx. 50 tons. had floated up, drained, and established the ability to swim. The pontoon was floated the same way. First the installed excavator was loosened and brought to shore. In the second step the buoyancy of the pontoon was established.

All three companions are back in the harbor, swimming. The engine of the first recovered pushboat was already running after two days of recovery. The rescue work was carried out in cooperation with Aqua-Nautik GmbH in a subcontractor contract.

Catamaran in Lake Müritz near Waren, 22 ton.

The catamaran "Antonia" was in Lake Müritz at a depth of 20 feet, about 1000 feet from land. The information showed that the shipwrecked ship was lying on his port side, there were open floats and that diving into the shipwrecked ship was too dangerous.

The rescue work was carried out by a work barge directly on site. First, the catamaran was turned on its hull side. Due to the shallow water, the cradle principle was used, i.e. the damaged vessel floats up like a cradle made of lifting bags. By shifting weight, the lifting bags were hung and the damaged ship was towed to the port of Sietow. Here the cradle principle was used again and the Antonia was raised to a depth of 6 feet and towed to the pier of the port. When it layed with her head in front of the pier, the swimmers were drained and all water inlets were closed. All leakages were sealed for further carry-over in order to avoid another accident.

The Antonia was handed over self-swimming!

Grab recovery in gravel plant I

On the part of the gravel plant, it was stated that the grab had been torn off and is at approx. 65 ft. After the first dive, we found that the grab was not buried and could be recovered without further effort. After the wire ropes were attached to the grab, we heaved it onto deck from a depth of 65ft. New wire ropes have been attached and the grab went on tour again. The entire action amounted to 4.0 hours of work.

Grab recovery in gravel plant II

The grab of a gravel excavator was buried at a depth of 65 feet, i.e. the earth collapsed during the excavation, the ropes came under tension and broke. As a result, the only connection between the grab and the gravel excavator was the associated power cable.

Our task was to find an attachment point on the gripper to bring it back to the surface. The first thing we did was look for the broken rope. Fortunately, we found it at short notice, so the use of lift bags was not necessary.

Because the wire ropes didn't look very promising, we treated the whole thing with extreme caution. The connected wire ropes threatened to slip into one another, so we decided to attach and lift the grab with a recovery chain and an intact wire rope. Shortly afterwards, the gripper saw the surface.

Emergency deployment 20 ton suction excavator salvage in Emsland

In the night from Monday to Tuesday, August 3rd, a suction excavator broke down in the Emsland. Professional help was required here to recover the suction excavator as quickly as possible. The search for a company with experience in the recovery of suction excavators brought the operator of the system directly to Aqua-Nautik GmbH. Master diver Carsten Thörmer was able to advise the customer competently and offer him quick help.

Aus noch unerklärlichen Gründen ist im Emsland am 03. August ein Saugbagger havariert. Schnelle und professionelle Hilfe war gefordert. Die Recherche nach einem Unternehmen mit Erfahrung im Bergen von Saugbaggern, führte den Betreiber der Anlage direkt zur AQUA-NAUTIK GmbH. Bei einem ersten Telefonat konnte Tauchermeister Carsten Thörmer den Kunden kompetent beraten und ihm schnelle Hilfe zusichern.

Noch am gleichen Tag begann die AQUA-NAUTIK GmbH mit der Zusammenstellung des benötigten Equipments, welches am nächsten Morgen verladen und zum Einsatzort transportiert wurde. Nach dem Montieren und Einrichten der Arbeitsplattform, fuhren die Taucher mit dem Schubboot an die Stelle, wo der Havarist zu finden war. Während einer kurzen Besprechung mit dem Fahrzeugführer des Baggers und dem Betriebsleiter, machten sich die Taucher anhand einer Skizze mit allen wichtigen Informationen über den Saugbagger vertraut. Bei einem ersten Erkundungstauchgang wurde bereits festgelegt, wo und an welchen Stellen des Saugbaggers die Hebesäcke installiert werden und in welcher Reihenfolge sie später gefüllt werden.

Am nächsten Tag verlegten die Taucher zunächst eine ca. 100 Meter lange Schlauchleitung, die über die Pontonanlage, die einzelnen Hebesäcke füllen soll. Die gute Vorbereitung zur Installation der einzelnen Hebesäcke führte dann dazu, dass die Taucher der Aqua-Nautik bereits im ersten Tauchgang, vier Hebesäcke mehr installieren konnte als es ursprünglich geplant war. Die verbliebenen Hebesäcke wurden dann in einem zweiten Tauchgang installiert. Die Luftleitungen der insgesamt zehn Hebesäcke wurden ordnungsgemäß aufgeschossen und gesichert.

Der weitere Ablauf der Bergung wurde mit dem Auftraggeber besprochen und für den frühen Samstag morgen geplant. Durch das Füllen der Hebesäcke in der festgelegten Reihenfolge konnte der Saugbagger problemlos gehoben und zum Ufer gezogen werden. Von dort aus konnte der Auftraggeber mit eigenen Geräten den Saugbagger an Land bringen, um eine schnelle Wiederaufnahme des Betriebs in Gang zu setzen.

Suction excavator, 120 ton

As is so often the case, a 120 ton suction excavator went aground for an unknown reason. The water depth was approx. 20-30ft, which made it possible to work under water indefinitely (without paying attention to decompression). After the attachment points have been found, 125 to. Lift bags have been attached. When all the lift bags were blown, this excavator was swimming again. It was moved close to the shore and hoisted ashore with two cranes. The rescue work was carried out in cooperation with Aqua-Nautik GmbH in a subcontractor contract.

Suction dredger

The decommissioned suction dredger of a gravel works, which was left to its own devices, leaked through a fine crack in the engine room and thus slowly but steadily filled with water. When the laws of physics struck with all severity, this one too broke down.

The owner was lucky because it was quite close to land and the use of lifting bags was not necessary. The leakage and water inlets were closed and the engine room was drained. When the excavator swam, the crack was closed and the excavator was left at sea in the hope that no further hairline crack would occur elsewhere.

"Suction excavator, 70 ton

The dredger was in the middle of the lake at a depth of 60 feet. When all the work materials had been loaded onto boats and pontoons, the lifting bags that were intended to be fastened began to be attached. It turned out to be a little difficult to find suitable attachment points in the dark water. Visibility was less than 4 inches, meaning you could barely see your hand in front of your eyes. After all the bags were well secured, the floats could start to blow.

The excavator moved to the surface from a depth of 60 feet, its position was stable. Thus, the approx. 650ft long transport route could begin near land. There were two cranes on land, ready to lift the excavator. The chain slings were attached and slowly and carefully pulled the damaged vessel ashore. The rescue work was carried out in cooperation with Aqua-Nautik GmbH in a subcontractor contract.

Coal freighter in the Mittelland Canal

In September 2003, in the early hours of the morning, a Polish coal freighter collided with a Dutch ship in thick fog on the Mittelland Canal near Minden. During the collision, the unloaded coal freighter was torn open at the starboard stern over a length of approx. 15ft. The crack went along the engine room below the waterline. The freighter filled up immediately and fortunately the crew “only” could save themselves with wet feet.

The responsible WSA reacted quickly and brought the transverse damaged vessel to the right bank, which enabled the rest of the shipping traffic to be maintained. Our task was to bring the damaged vessel back to the surface.

By closing the water inlets and the locker on the hold, we succeeded in draining the freighter and making it floatable. The salvage work was carried out in cooperation with Aqua-Nautik GmbH.

SOS, the ship is gone

The ship owner was visibly shocked when he saw only the cabin roof of his ship in the harbor in the early morning. The ship sank within a night. The divers from Aqua-Nautik were quickly on site to rescue the damaged ship with lifting bags and a crane. Defective seals on the propeller were probably to blame for the sudden ingress of water.

Materialversagen war die Ursache für die havarierte Petra´s im Hafen Köln-Porz/Zündorf. Defekte Packungen an der Schiffsschraube führten zu einem plötzlichen Wassereinbruch, der das Boot innerhalb einer Nacht sinken ließ. Als der Schiffseigner am Morgen zum Hafen schaute, stellte er fest, dass nur noch die Spitze seines Schiffes aus dem Wasser ragte.

Bergungen zählen zu den häufigsten Aufgaben der Aqua-Nautik GmbH. Daher war die Zusammenstellung des erforderlichen Equipments in kürzester Zeit erledigt. Bereits am nächsten Morgen machten wir uns mit zwei Fahrzeugen nebst Bootsanhänger auf dem Weg nach Köln Zündorf. Nach unserem Eintreffen wurde sogleich das Einsatzboot ins Wasser gelassen und mit der weiteren Aufrüstung begonnen. Der Havariekommissar, welcher von der Versicherung bestellt wurde, koordinierte die weiteren Arbeiten und orderte neben dem Hebekran auch die Traverse und den Trailer mit dem das Schiff schlussendlich abtransportiert werden sollte.

Das Verbringen der Hebesäcke am havarierten Schiff bereitete keine Schwierigkeiten, das recht flache Wasser im Hafen schon eher. Demzufolge musste das Schiff erst an geeigneter Stelle verholt werden wo das Heben des Schiffs auch für den Kran kein Problem mehr darstellte.

Recovery of boats and yachts

The recovery of sport boats and yachts in harbors and in coastal waters is also part of our area of responsibility.

We make it our goal to salvage sports boats and especially yachts with absolute damage limitation. Because the owner and the insurer are mostly interested in getting the damaged items back in one piece.

Offshore-Boat

An offshore boat lying on the pier struck a leak in the late afternoon hours and sank over its starboard stern.

In order to limit the damage quickly, we immediately went out for the rescue. Because the port side of the damaged vessel was firmly attached to the pier, the recovery proceeded quickly and smoothly.

The leak was located, sealed, and the boat was tendered by the local DLRG and handed over to custody for further assessment.

Cabin boat

An abandoned cabin boat lying in the marina has suffered water ingress as a result of improperly leaving it and consequently went aground. The boat was lifted with the help of a truck crane and brought ashore to secure it. The rescue operation took about 3.0 hours.

Barge in the port of Peenemünde

In April 2007 we were entrusted with the salvage of a 130ft long and 16ft wide former living ship in the Peenemünder Hafen. The living ship had been lying on the harbor for about 1 1/2 years. Therefore, it was more a question of wreck removal than salvage in the true sense of the word.

The ship was about 3ft in the mud due to the harbor basin directly at the pier. After lifting straps had been undermined and the hull of the wreck had been exposed, the lifting of the damaged vessel began.

A 200 ton and a 120 ton truck crane from Lange were used as the lifting device. Lifting turned out to be a bit difficult, as the ravages of time in the 1 1/2 years that the ship had spent on the harbor had gnawed at it a lot. The entire lifting action and the dropping on land ended successfully with the efforts of all those involved. Special thanks also go to the tireless efforts of KRANDIENST LANGE, who hoisted the damaged goods (Swiss cheese) ashore with a lot of tact and energy.

Pump pontoon in the ice

A pumping pontoon sank in a chalk plant in the north of Germany. The only connection between the pontoon and the land was a jetty. What saved the damaged vessel from complete sinking was the air bubble in the front part of the pontoon. Due to the extreme weather conditions in 2009/10, the prospect of a successful recovery was to be viewed very critically from the start. Thanks to our extreme snow chains, we still reached the accident position through ice and snow. Now that the position of the pontoon had stabilized and the area around the pontoon could be kept free of ice at -10 degrees Celsius, the bilge began.

When the pumping pontoon had now returned to its original position, research into the causes began. Ultrasonic measurements have shown that the remaining wall thickness is too small. For this reason, it was decided together with the operator to make the pontoon unsinkable. We are sure that the operator now has one less problem on his chalk plant.

Salvage girder grate in Norway Askim - Norway July 2010

Background information on the project:

The girder grate to be recovered served as a platform for a formwork for the bridge pillar of the “Smaalenene Bru”, which was to be built later.

The girder grid was originally attached to a pontoon on the left and right. On top of this, a formwork in the shape of a cylinder was erected. After appropriate construction, the formwork was left underwater bit by bit, so that gradually a self-floating formwork with a height of approx. 115 ft was created.

After the formwork swam independently due to the buoyancy achieved, the girder grating had initially fulfilled its task. The construction progress was therefore in full swing and the bridge got its main pillar. At the end of the construction work, the girder grid also had to be recovered from a water depth of around 115 ft, which was commissioned to us.

The ROV inspection initially provided information about the location and effort of the expected salvage work. Due to the depth of the water, the dives could be planned and carried out explicitly. The preparatory work took about 4 days. During this time, buoyancy devices of 70 tons were installed. The rescue was carried out after successful lifting and moving near land on day 5 with a 500.0 ton truck crane from Mammoet. The girder grate was handed over to the client lying on land and the recovery was thus successfully carried out.

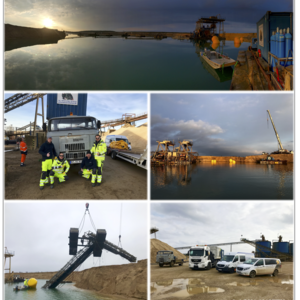

Aqua-Nautik recovers a gravel conveyor system after deep depression

Shortly before Easter, hurricane "Niklas" wreaked havoc across Germany. This was also the case in a gravel pit, where the storm caused several floating pontoons to leak from Tuesday to Wednesday and put an approx. 100 ft large section of the gravel conveyor system on the ground. Here, the quick deployment of Aqua-Nautik GmbH was required to prevent further damage. The task was: Securing and restarting as well as salvage of the damaged part of the conveyor system.

Such an order requires a lot of equipment. Aqua Nautik advanced to the scene of the accident with two trucks, fully loaded with pontoons, as well as two transporters including trailers and boats. In addition, a 60 ton mobile crane was ordered, which brought the required material safely onto the water.

One of the first tasks on site was securing the existing system, which threatened to be torn down if the wind conditions continued to be poor. For this purpose, 2x2 coupling pontoons were pushed right and left under the conveyor system in order to secure the conveyor belts that were still intact. This enabled the Aqua-Nautik team to prevent further damage to the system.

For the following work processes, the base platform has now been built from additional pontoons. It carried all the equipment such as the diving container, the generator, the winch and the A-mast. The A-mast in connection with the cable winch served as a crane. It was needed for the further securing and recovery of the individual sunken elements. The platform was pushed to the scene by boat.

A first dive on site brought clarity about the further procedure for salvaging the conveyor system. The storm had caused more damage than initially thought. The leaking pontoons had rotated and thus considerably damaged the gangway of the conveyor belt. As time was of the essence, as the conveyor system had to be put back into operation as soon as possible, the team decided to carry out a recovery in several stages.

The damaged area was now primarily secured and separated from the existing system. The electrics and the tapes were recovered undamaged. Now the areas that were still intact could be moved and brought together again. This enabled the operator to have the conveyor system repaired immediately and put back into operation the next day. The gangway that remained in the water, together with the remaining leaky pontoons, could ultimately be lifted while the gravel was being conveyed.